منصة نقالة الحبوب المعبأة

منصة نقالة هاون

منصة نقالة الكرتون

Feed grain palletizer

Fertilizer palletizer

Paint bucket palletizer

منصة نقالة الحبوب المعبأة

منصة نقالة هاون

منصة نقالة الكرتون

Feed grain palletizer

Fertilizer palletizer

Paint bucket palletizer

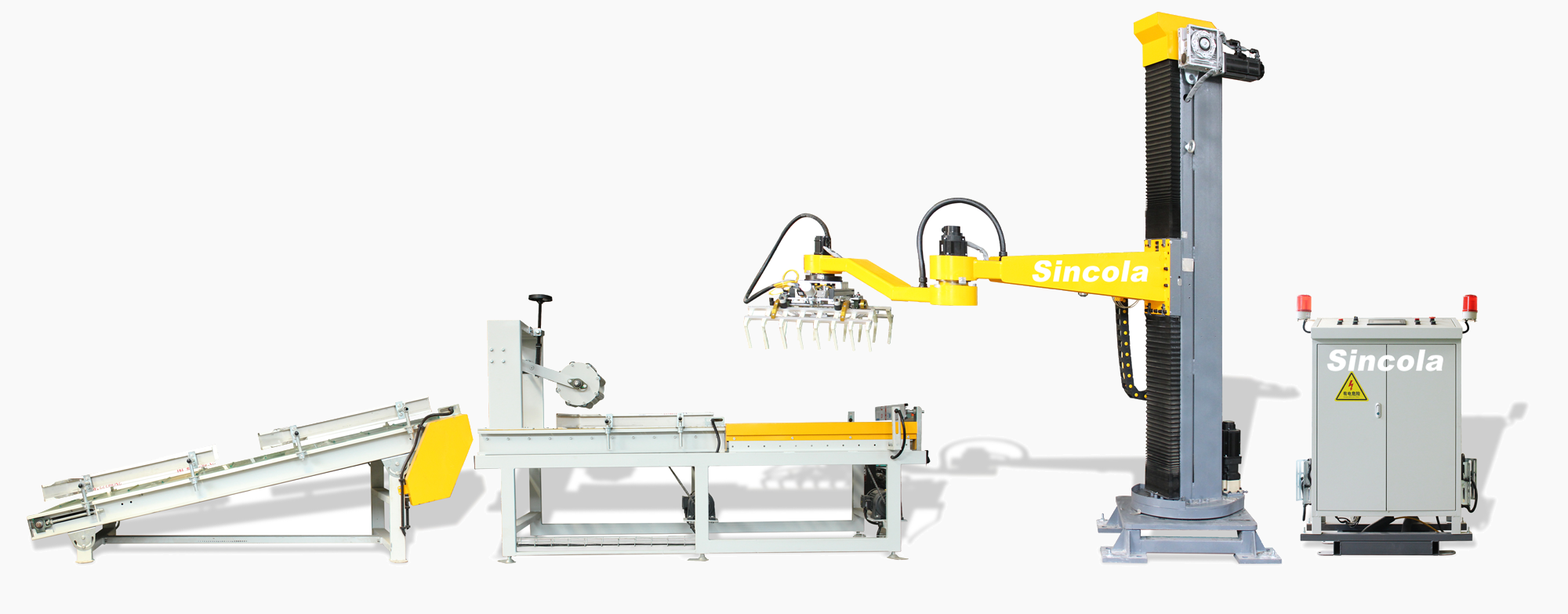

نموذج:سلز-400MD

كفاءة البليت: 400 مرات / ساعة

الحمولة القصوى: 100كلغ

الحد الأقصى لنطاق النشاط: 1950مم

كرر دقة تحديد المواقع:+0.3مم

نطاق العمل:

المحور S: تربة 180 °

المحور Z: 1800مم

محور R: تربة 180 °

سيارات الأجرة: تربة 360 °

المنتجات القابلة للتطبيق: شنطة, صندوق, حاجز, ورق مقوى, لوح خشبي, إلخ.

إمدادات الطاقة إمدادات الطاقة: 3*ايه سي 380 + ن

ارتفاع المنصات: 1600مم (يمكن تخصيص أحجام أخرى)

مصدر الهواء: 0.4-0.6mpa

وزن: 1500كلغ

The Column Robot Palletizer machine adopts a robot control system to achieve linear interpolation from point to point, مما يجعل الحركة سلسة وسائلة.

تتحكم قلادة التدريس في حركة الروبوت الصناعي من خلال وظائف التحكم والعرض الرئيسية, مما يسمح للمشغلين بالتدريس والتحكم في حركة محدد الموضع بسلاسة.

يمكن تخزين نمط التراص مسبقًا وتشغيله بمرونة للإضافات اللاحقة.

يمكنها استكمال عملية تكديس المنتجات المعبأة في أكياس وفقًا لطريقة التجميع والطبقات المطلوبة أثناء التشغيل.

Packaged materials are conveyed to the designated palletizing area. The columnar robot, through the coordination of each axis, moves the fixture to directly above the material’s position.

When the material positioning signal is sent, the fixture moves downward (Z-axis downward motion) controlled by a servo motor.

When the fixture reaches the height for holding the material, the Z-axis stops descending, the fixture opens and grips the material.

The Z-axis servo motor reverses, lifting the fixture to a safe height and transporting the material to the palletizing position according to the customer’s preset program.

The Z-axis descends, placing the material at the designated point. At this point, the fixture opens, placing the material in the specified position. After completing the entire palletizing process, an alarm sounds to indicate completion. The forklift then removes the pallet and places it on a new one, ready for the process to repeat.

The Column Robot Palletizer equipment is widely applicable to the packaging and palletizing needs of finished products in various shapes, such as cartons, أكياس, cans, boxes, and bottles, in production enterprises within the feed, chemical, beverage, طعام, beer, plastic, and refractory material industries.

السابق: منصة نقالة روبوتية لعمود الملاط