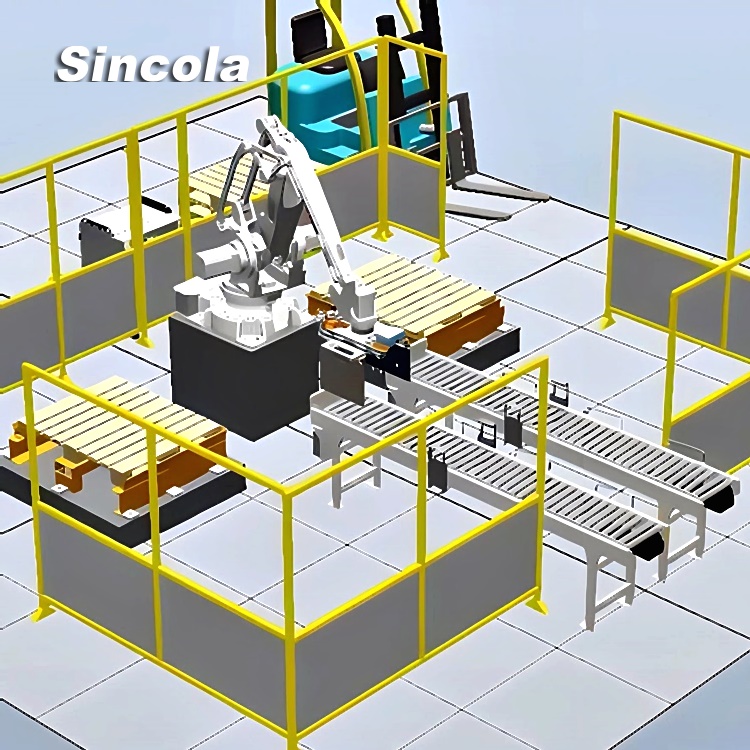

In today’s fast-paced and efficient production environment, البليت الآلي has become an indispensable assistant on modern production lines. It not only significantly reduces manual labor, thereby improving work efficiency, but also lowers production costs. This article will take you through the advantages of zhengzhou sincola robotic palletizing and how to achieve efficient application on the production line.

كيس هاون روبوت منصة

Robotic palletizing possesses the following significant advantages:

Labor-saving: It can replace manual labor to complete heavy and repetitive palletizing work, reducing the burden on workers and avoiding human errors in operations.

Improved efficiency: Operating 24/7 without time and location constraints greatly enhances production efficiency.

Cost reduction: It reduces labor costs and lowers the risk of production accidents and compensation.

High reliability: Its high level of automation and stability ensures the accuracy and consistency of palletizing, reducing the possibility of interference from human factors on the production line.

عمود تغذية الحبوب منصة نقاش

II. Application of Robotic Palletizing on the Production Line

Robotic palletizing is an indispensable part of automated production lines, mainly performing the following tasks:

Handling: Quickly and accurately gripping goods on the production line and moving them to designated locations.

Palletizing: Stacking and arranging goods neatly according to preset programs to form stable pallet patterns.

Real-time adjustments: Monitoring the position and orientation of goods in real time through sensors and control systems to ensure accurate palletizing.

Fertilizer feed bagging palletizing machine

III. Maximizing the Benefits of Robotic Palletizing

To fully leverage the advantages of البليت الآلي, improve production efficiency, and reduce costs, attention should be paid to the following:

Selecting the right model: Choose a suitable robotic palletizer based on actual needs and the characteristics of the goods.

Optimizing programs and instructions: Continuously optimize the robot’s programs and instructions to make it work more efficiently.

Regular maintenance and upkeep: Ensure the robot’s normal operation and extend its service life.

Training and guidance: Provide training for operators to ensure they can fully utilize and maintain the robot.

IV. Conclusion

Robotic palletizing has played a significant role on production lines, reducing manual labor, improving work efficiency, and saving substantial costs for businesses. Choosing the right robot, continuous optimization, regular maintenance, and providing comprehensive training are key to maximizing its benefits. بالإضافة إلى ذلك, ensuring safe operation is also crucial. With continuous technological advancements,zhengzhou sincola robotic palletizing will demonstrate its outstanding value in more fields.

تشنغتشو سينكولا

تشنغتشو سينكولا