Palettiseur

Palettiseur

Palettiseur

Palettiseur

Palettiseur

Palettiseur

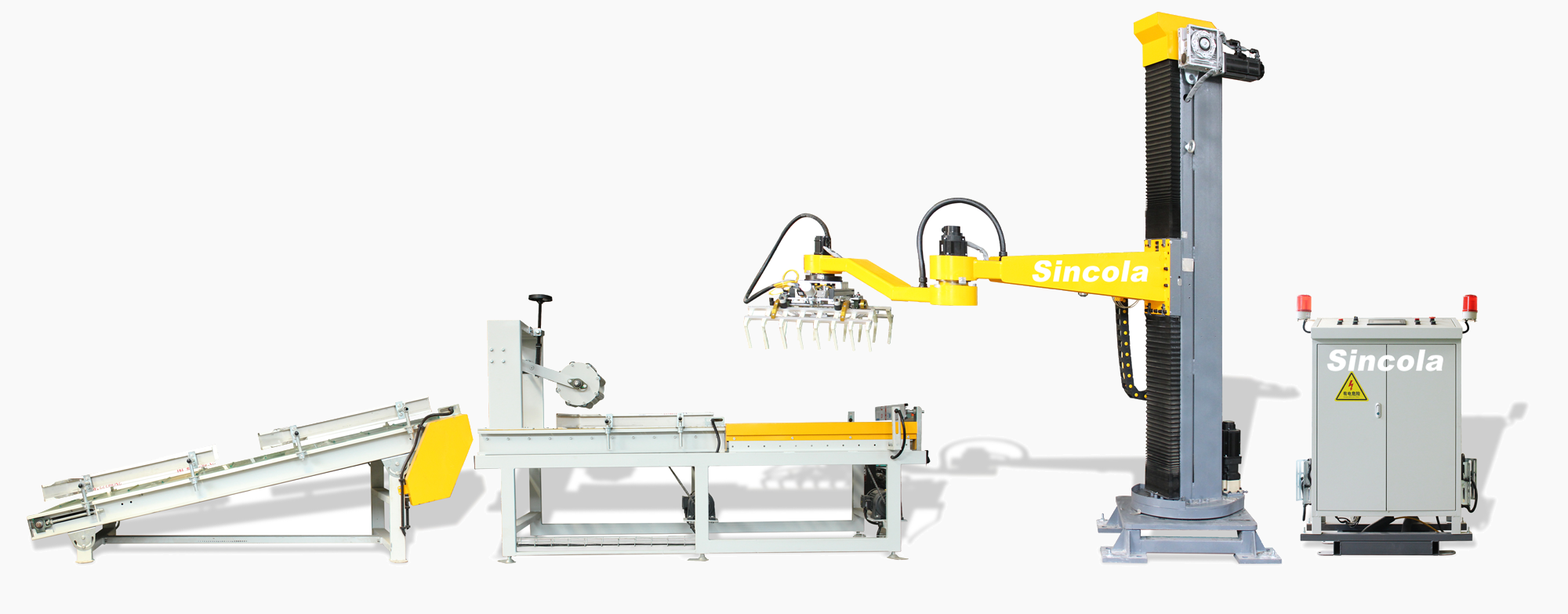

Modèle:SDB-400MD

Efficacité de la palettisation: 400 fois/h

Charge maximale: 100kg

Rayon d'activité maximum: 1950mm

Répéter la précision du positionnement:+0.3mm

Plage de travail:

Axe S: sol 180 °

Axe z: 1800mm

Axe R: sol 180 °

Taxis: sol 360 °

Produits applicables: sac, boîte, bloc, papier carton, planche de bois, etc..

Alimentation électrique: 3*AC380+N

Hauteur de palettisation: 1600mm (d'autres tailles peuvent être personnalisées)

Source d'air: 0.4-0.6mpa

Poids: 1500kg

The column straight arm palletizer adopts a robot control system to achieve linear interpolation from point to point, rendre le mouvement lisse et fluide.

Le pendentif Teach contrôle le mouvement du robot industriel grâce à des fonctions de contrôle et d'affichage des clés, Permettre aux opérateurs d'enseigner et de contrôler en douceur le mouvement du positionneur.

Le motif d'empilement peut être pré-stocké et exploité de manière flexible pour des ajouts ultérieurs.

It can complete the column straight arm palletizer of bagged products according to the required grouping method and layers during operation.

Column straight arm palletizer Packaged materials are conveyed to the designated palletizing area. Le robot colonne, par la coordination de chaque axe, déplace le luminaire à directement au-dessus de la position du matériau.

Lorsque le signal de positionnement du matériau est envoyé, Le luminaire se déplace vers le bas (Mouvement vers le bas de l'axe z) contrôlé par un servomoteur.

Lorsque le luminaire atteint la hauteur pour maintenir le matériau, L'axe Z s'arrête descendant, Le luminaire ouvre et saisit le matériau.

Le servomoteur de l'axe Z s'inverse, Soulever le luminaire à une hauteur sûre et transporter le matériau vers la position de palettisation selon le programme prédéfini du client.

L'axe z descend, Placer le matériau au point désigné. À ce point, Le luminaire s'ouvre, Placer le matériau en position spécifiée. Après avoir terminé l'ensemble du processus de palettisation, Une alarme sonne pour indiquer l'achèvement. Le chariot élévateur retire alors la palette et le place sur un nouveau, Prêt pour que le processus se répéte.