Modèle:SSGW-800MD

Capacité de sortie: 600-800 sacs/h

Tension: 380V 50Hz trois lignes en trois phases

Puissance de course: 7KW-10KW

Taille: 5700x2200x3100 (mm)

Nombre de couches palettisées: 1-12 couches

Pression d'origine aérienne: 0.6-1.0MPA

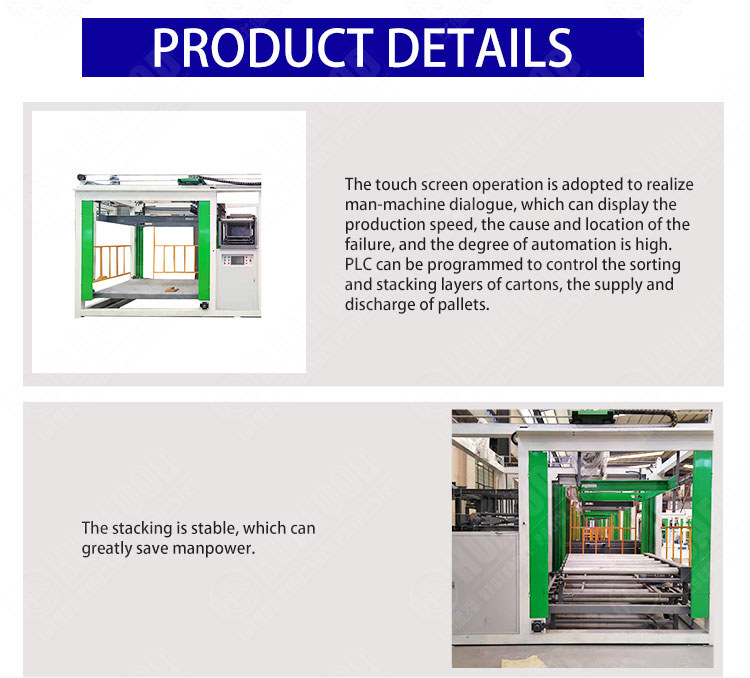

Palettiseur à double station Un système de contrôle du robot pour obtenir une interpolation linéaire d'un point à l'autre, rendre le mouvement lisse et fluide.

Le pendentif Teach contrôle le mouvement du robot industriel grâce à des fonctions de contrôle et d'affichage des clés, Permettre aux opérateurs d'enseigner et de contrôler en douceur le mouvement du positionneur.

Le motif d'empilement peut être pré-stocké et exploité de manière flexible pour des ajouts ultérieurs.

Il peut compléter la palettisation des produits en sac en fonction de la méthode de regroupement et des couches requises pendant le fonctionnement.

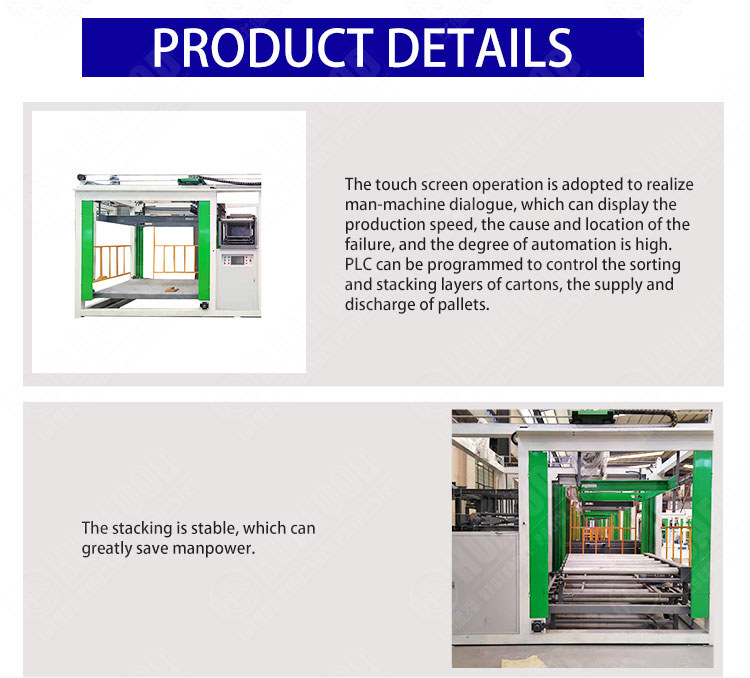

Haut palettiseur robot Les matériaux emballés sont transmis à la zone de palettisation désignée. Le robot colonne, par la coordination de chaque axe, déplace le luminaire à directement au-dessus de la position du matériau.

Lorsque le signal de positionnement du matériau est envoyé, Le luminaire se déplace vers le bas (Mouvement vers le bas de l'axe z) contrôlé par un servomoteur.

Lorsque le luminaire atteint la hauteur pour maintenir le matériau, L'axe Z s'arrête descendant, Le luminaire ouvre et saisit le matériau.

Le servomoteur de l'axe Z s'inverse, Soulever le luminaire à une hauteur sûre et transporter le matériau vers la position de palettisation selon le programme prédéfini du client.

L'axe z descend, Placer le matériau au point désigné. À ce point, Le luminaire s'ouvre, Placer le matériau en position spécifiée. Après avoir terminé l'ensemble du processus de palettisation, Une alarme sonne pour indiquer l'achèvement. Le chariot élévateur retire alors la palette et le place sur un nouveau, Prêt pour que le processus se répéte.

Haut palettiseur robot est largement applicable aux besoins d'emballage et de palettisation des produits finis de différentes formes, comme les cartons, Sacs, canettes, boîtes, et les bouteilles, dans les entreprises de production dans le flux, chimique, boisson, nourriture, bière, plastique, et industries des matériaux réfractaires.

Précédent: Palettiseur de cartons de haut niveau