Bagged grain palletizer

Column mortar palletizer

Mortar palletizer

Bagged grain palletizer

Column mortar palletizer

Mortar palletizer

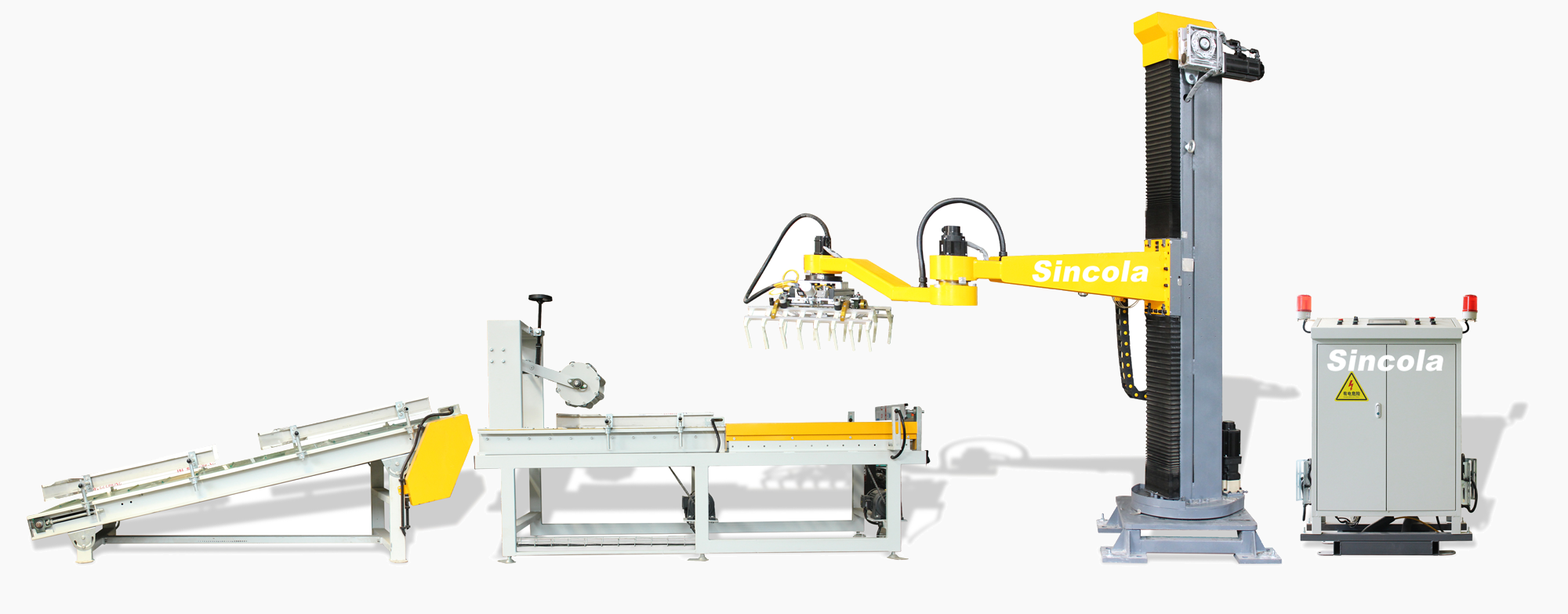

Model:SLZ-400MD

Palletizing efficiency: 400 times/h

Maximum load: 100kg

Maximum activity radius: 1950mm

Repeat positioning accuracy:+0.3mm

Working range:

S axis: soil 180 °

Z axis: 1800mm

R axis: soil 180 °

T -axis: soil 360 °

Applicable products: bag, box, block, cardboard, wooden board, etc.

Power supply power supply: 3*AC380+N

Palletizing height: 1600mm (other sizes can be customized)

Air source: 0.4-0.6mpa

Weight: 1500kg

The mortar, putty powder, and gypsum powder palletizing machine is an automated equipment used in the production line of mortar, putty powder, and gypsum powder. It efficiently stacks bags of these materials and achieves automatic loading and unloading, greatly improving production efficiency and operational benefits.

Characteristics and Working Principle of the Mortar, Putty Powder, and Gypsum Powder Palletizing Machine: The palletizing machine has the following

It utilizes an automated control system to precisely control actions, achieving high-speed and high-precision palletizing operations.

It is multifunctional, allowing flexible adjustments and settings according to different product requirements.

Advanced sensor technology enables real-time monitoring of the stacking status of the materials, ensuring operational accuracy and reliability.

Highly intelligent, capable of autonomous adjustment and optimization to enhance production efficiency.

The working principle of the palletizing machine involves several steps:

Bags of mortar, putty powder, and gypsum powder are transported to the palletizing area by a conveying system, with sensors detecting the position and quantity of the bags.

The machine sequentially stacks the bags according to preset palletizing methods and rules, forming a neat stack.

The completed stack is automatically moved to make space for the palletizing of the next batch of bags.

Upon completion of the entire palletizing process, the machine automatically sends out the entire stack to prepare for subsequent processes.

Application Scenarios of the Mortar, Putty Powder, and Gypsum Powder Palletizing Machine: The machine is widely used in the production lines of mortar, putty powder, and gypsum powder, offering several advantages for manufacturers:

It enhances production efficiency, significantly reducing production cycles and costs.

It maintains the neat and stable stacking of the materials, avoiding human errors in manual palletizing.

The automated control system reduces labor intensity and improves work safety.

It can be customized to meet the palletizing requirements of different users.

Future Development Direction of the Mortar, Putty Powder, and Gypsum Powder Palletizing Machine: As industrial automation continues to advance, the palletizing machine may follow these development trends:

Equipped with more intelligent control systems and sensor technology for more precise and rapid operations.

Operated through human-machine interaction interfaces for simpler and more intuitive operation.

Seamlessly connected with other intelligent devices to achieve the automation of the entire production line.

Implementation of remote monitoring and management to enhance production line efficiency and operational benefits.

In summary, the mortar, putty powder, and gypsum powder palletizing machine is an efficient and intelligent equipment for production lines, achieving high-speed and high-precision palletizing operations through an automated control system, significantly improving production efficiency and operational benefits. In the future, it is expected to evolve towards greater intelligence and automation as industrial automation continues to progress.