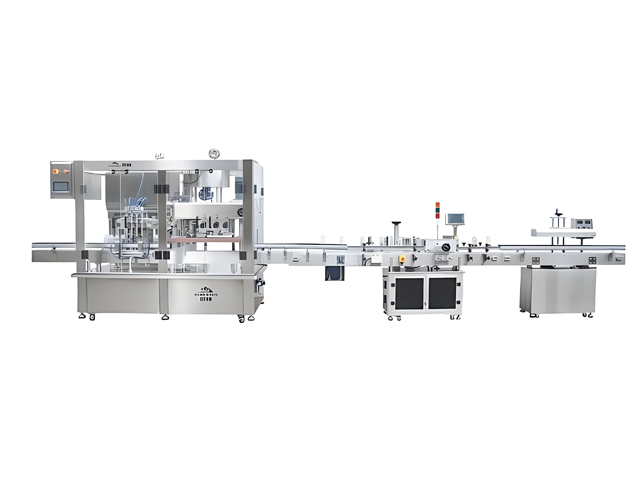

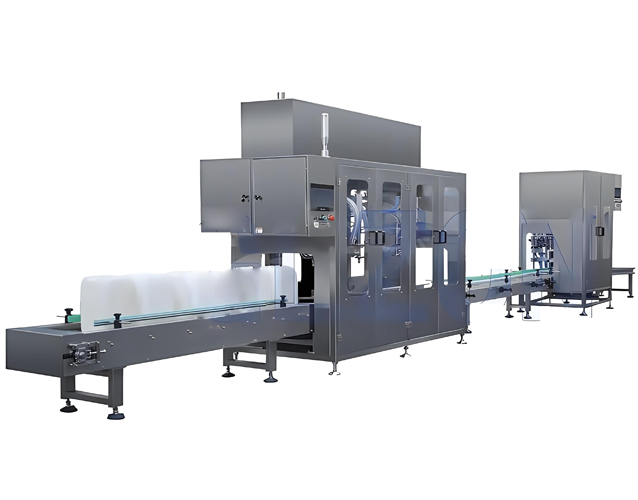

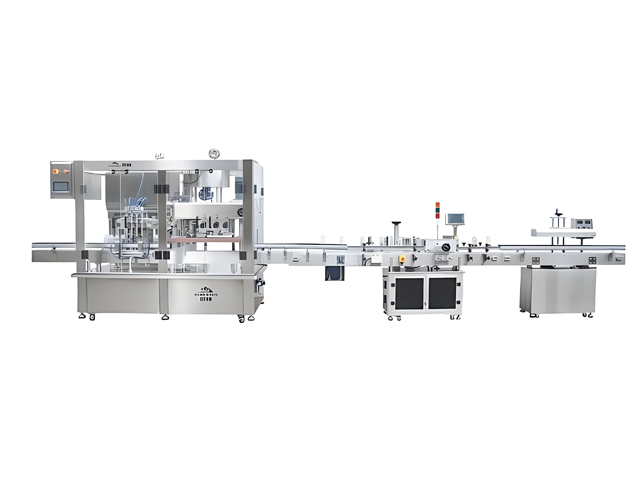

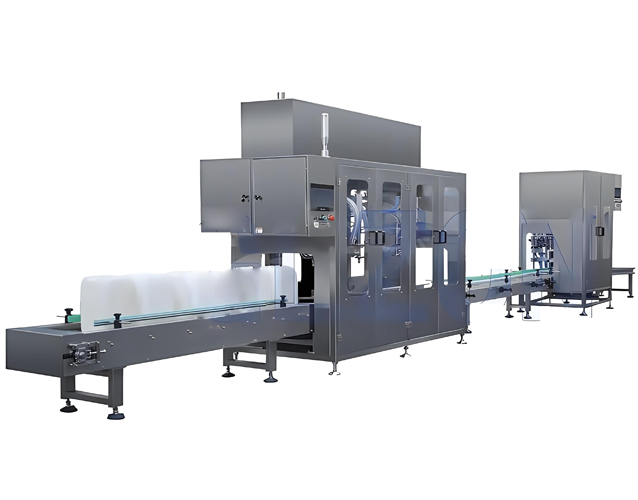

The automatic filling of various concentrations and viscosity liquids of oil, daily chemicals, chemical industry and other industries.

- This machine uses the working principle of self -flow to achieve the control of the amount of filling. During the filling, the signal is given by the weighing sensor, and the time to control the filling valve through the digital controller is controlled.

- The filling part of this machine consists of fast -filing, medium -sized installation, and slow filling. When the installation valve is opened at the beginning of the filling, the installation valve is all opened and fast -filled; the filling valve is closed until the fast -forward material value is installed to the middle of the irrigation. The installation valve is closed, and the slow -filled valve is opened and the pouring side material is turned on until the target weight.

- This machine is equipped with a special leakage device in the filling tube to prevent the drawing or dripping phenomenon when the viscous liquid is filled.

The above parameters are standard parameters, and the specifics may change according to the difference in material speed.