Robot barrel palletizer

Robot carton palletizer

Robot Mortar Palletizer

Robot barrel palletizer

Robot carton palletizer

Robot Mortar Palletizer

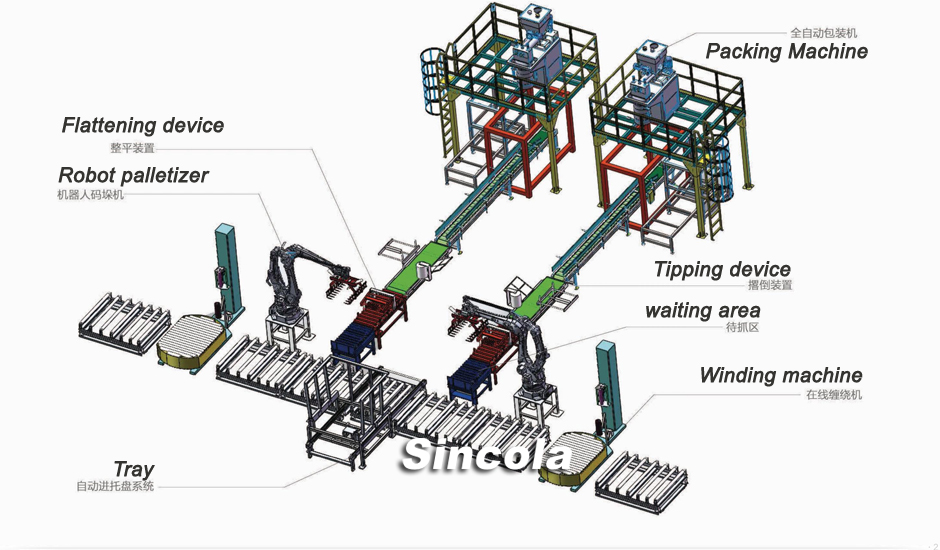

Robot palletizers are cutting-edge industrial machines designed to automate the process of stacking goods onto pallets, revolutionizing the way warehouses and distribution centers handle their products. These advanced systems utilize robotic arms and sophisticated software to efficiently and precisely arrange goods, significantly improving productivity and reducing the risk of workplace injuries.

One of the key features of robot palletizers is their versatility. These machines can handle a wide variety of products, including boxes, bags, and containers of different shapes and sizes. By utilizing advanced sensors and intelligent programming, robot palletizers can adapt to various production lines and efficiently stack products according to specific patterns and configurations.

The implementation of robot palletizers offers numerous benefits to businesses. Firstly, they greatly enhance operational efficiency by automating a task that was previously labor-intensive and time-consuming. This leads to increased throughput and allows employees to focus on more complex and value-added tasks. Additionally, robot palletizers contribute to a safer work environment by reducing the need for manual labor in potentially hazardous stacking operations.

Boxing product:

Production efficiency: 700-800 times/h

Applicable products: carton box

Carton size: according to user requirements

Packing method: according to user requirements

Power: 3*AC380+N

Equipment weight: 1.2T (body weight)

Barrel products:

Production efficiency: 600-800 times/h

Applicable products: barrels

Carton size: according to user requirements

Packing method: according to user requirements

Power: 380V

Equipment weight: 1.2T (body weight)