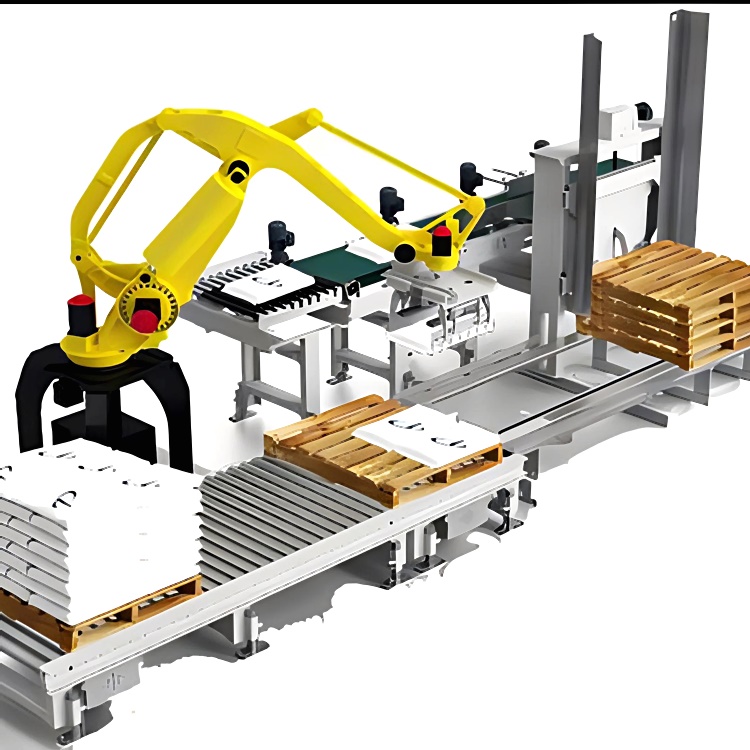

After completing a stack, the palletizing machine will automatically move it to a designated position, making space for the next stack. This automated design relieves us from worrying about space utilization issues, as the palletizing machine handles it properly.

Perfect Finale, Worry-Free Handling

Once the entire palletizing process is completed, the palletizing machine will send out the last stack, preparing adequately for our subsequent handling or storage. This eliminates concerns about handling after palletizing, truly providing a one-stop service from palletizing to handling.

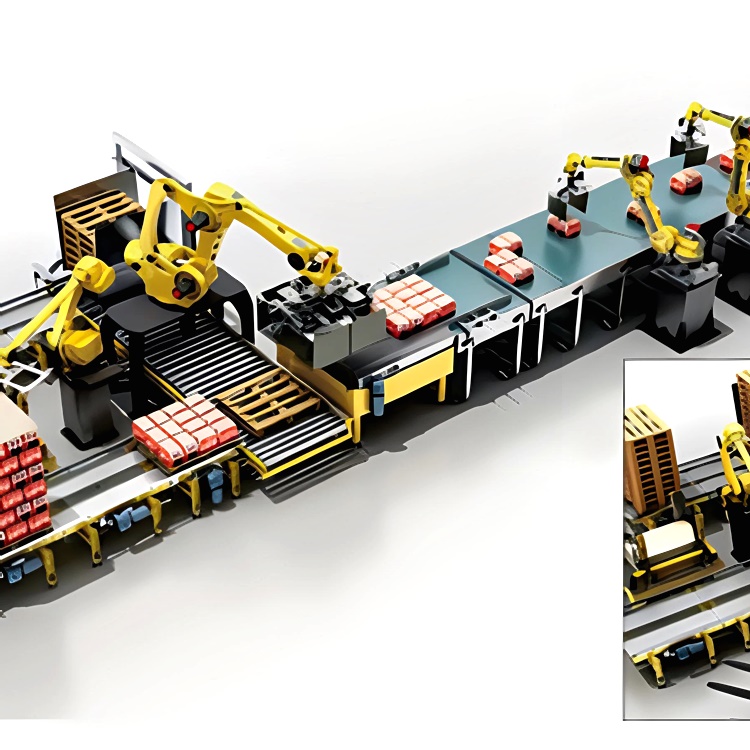

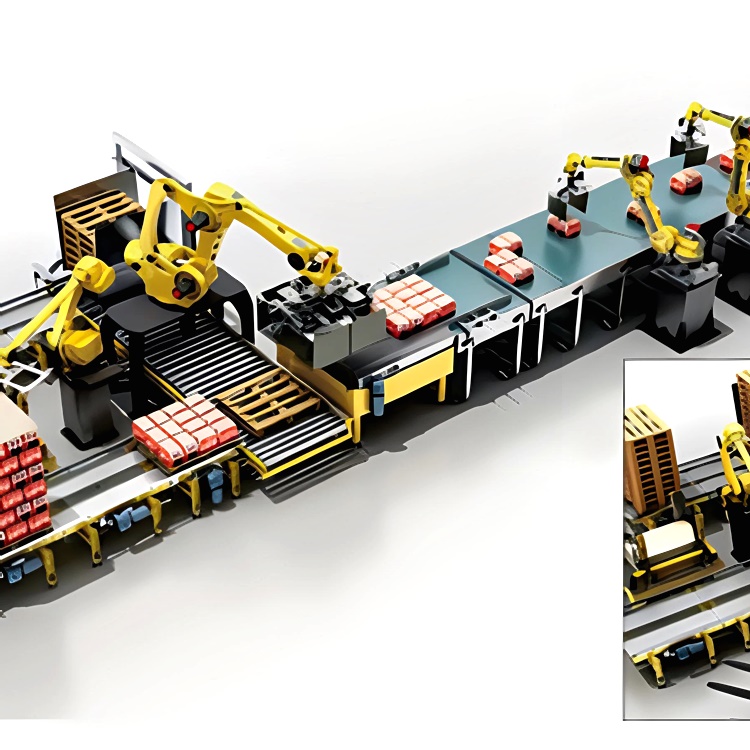

Collaborating with Other Equipment, Doubling the Results

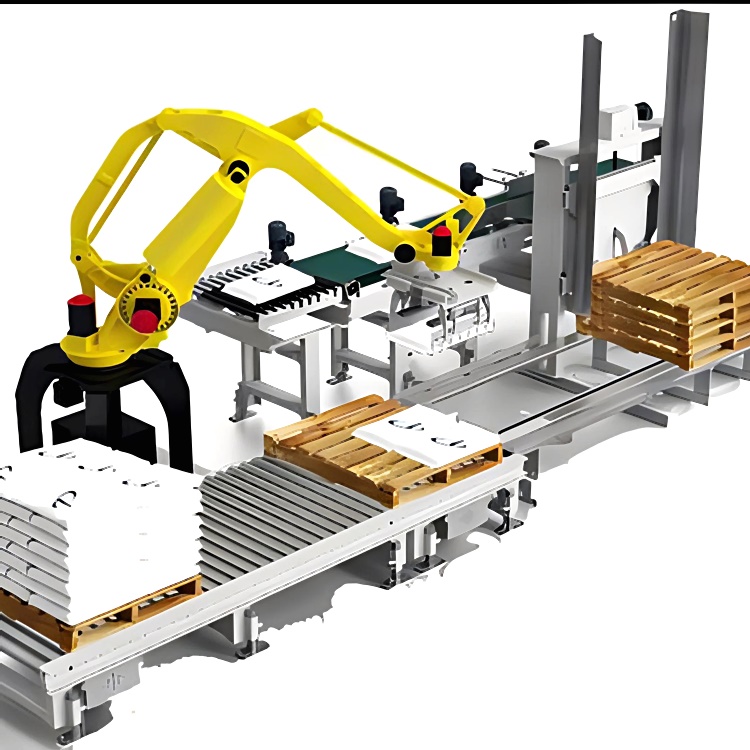

In practical applications, we also need to coordinate the palletizing machine with other equipment, such as conveying equipment, forklifts or stackers, and packaging machines. The collaborative work of these devices makes our entire workflow smoother and more efficient.

Is It Suitable for Small-Scale Workshops?

For small-scale workshops, whether to equip a palletizing machine is indeed a question worth considering. If the production scale is small, manual palletizing may be sufficient to meet daily demands. However, as the production scale expands, manual palletizing may not meet efficiency and quality requirements. Additionally, while the initial investment in a palletizing machine may be relatively high, in the long run, it can improve production efficiency and reduce labor costs, making it an economically viable choice. Furthermore, if the company plans to expand its production scale, introducing a palletizing machine in advance can prepare the enterprise for future expansion.

In conclusion, it is advisable for businesses to make informed decisions based on their specific circumstances regarding whether a palletizing machine is necessary for small-scale workshops. Considering the convenience, efficiency, and long-term economic benefits brought by the palletizing machine, it is undoubtedly a wise choice for enhancing production efficiency and reducing costs.